CNC Laser Cutting Computer numerically controlled (CNC) laser cutting is a sheet/tube metal fabricating process carried out by laser cutters, which uses an intense beam of light to cut materials. It is a highly precise thermal process often recommend...

Share

CNC Laser Cutting

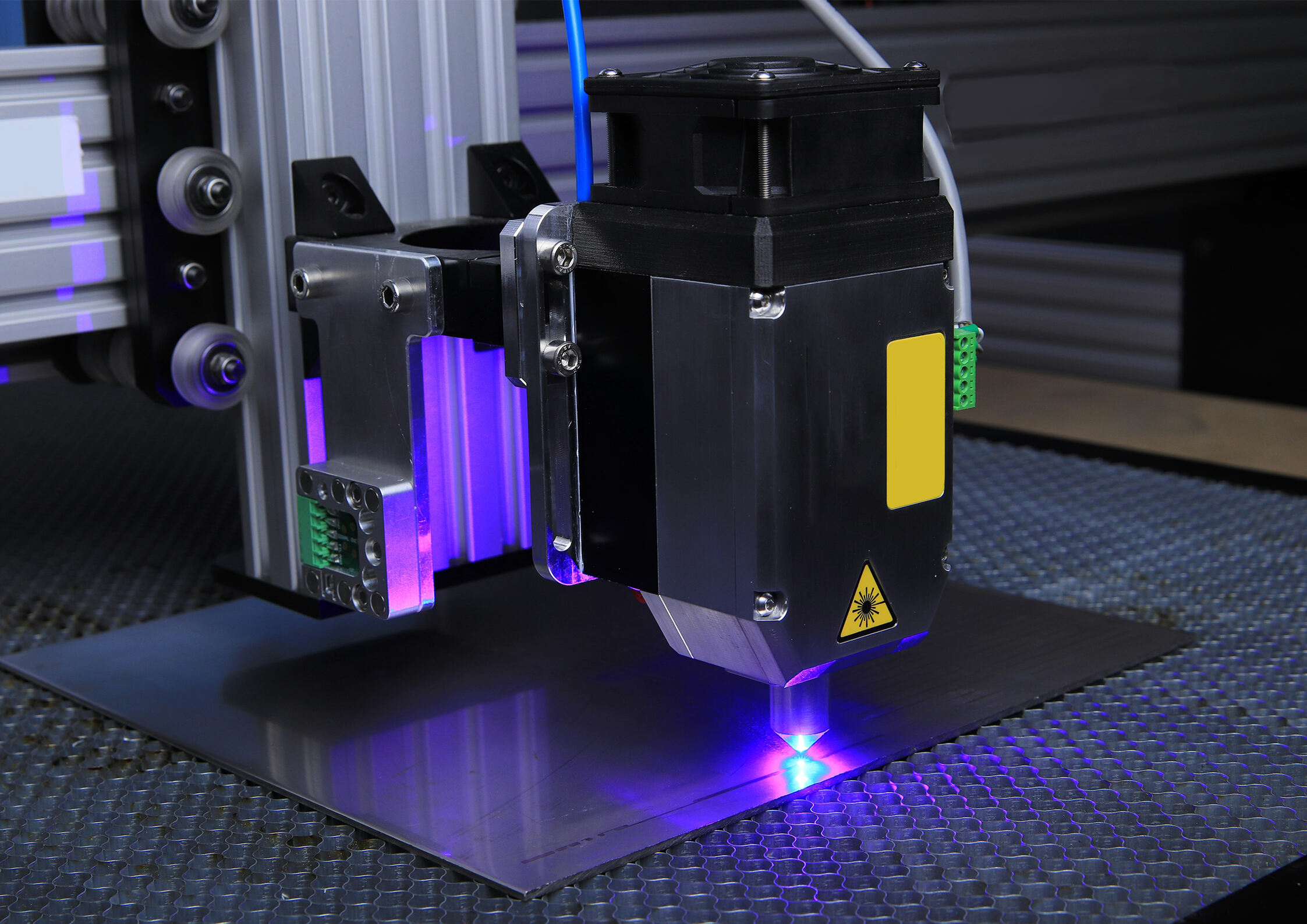

Computer numerically controlled (CNC) laser cutting is a sheet/tube metal fabricating process carried out by laser cutters, which uses an intense beam of light to cut materials. It is a highly precise thermal process often recommended in applications requiring tight tolerances, precise cutouts, or holes that are small in relation to the material thickness. This cutting process is ideally suited for many applications.

MATERIALS FOR LASER CUTTING

Lasers can cut through many different materials. Atlas Metal works with the following materials:

Atlas Metal specializes in high-quality laser cutting for prototype, low-volume, and high-volume orders.

Atlas metal OFFERS 2d flat and tube LASER CUTTING SERVICES

A video to show 2D flat laser cutting

Atlas Metal is a specialist in 2D Flat & tube Laser Cutting with years of experience in laser cutting to provide the cutting metal including stainless steel, carbon steel, and aluminum. Our cutting shop is equipped with advanced CNC laser cutting machines to stand ready to provide you with perfect services. The 2D laser cutting is applied to cut flat metal with various thicknesses, see the following parameter table as an example:

|

Item |

Specification |

Unit |

|

|

1 |

Sheet Cutting Size |

3000×1500 |

mm |

|

2 |

Stroke of X Axis |

3000 |

mm |

|

3 |

Stroke of Y Axis |

1500 |

mm |

|

4 |

Stroke of Z Axis |

280 |

mm |

|

5 |

Max. Feeding Speed |

140 |

m/min |

|

6 |

Cutting Accuracy |

±0.10 |

mm/m |

|

7 |

Rated Laser Power |

1000 |

W |

|

8 |

Cutting Thickness (when the required cutting condition is met) |

Carbon Steel 0.5-12 |

mm |

|

Stainless Steel 0.5-5 |

mm |

||

|

9 |

Stable Cutting Thickness |

Carbon Steel 10 |

mm |

|

Stainless Steel 4 |

mm |

video to show tube laser cutting

Tube Laser Cutting technology offers many new and different design options and gives designers the freedom to easily put any cutout shape into the tube, which is a highly productive and flexible method of tube processing.

Atlas Metal is equipped with tube laser cutting machines designed both to cut hole profiles on round, square, oval, triangular, and other special section tubes.

The tube laser cutting services that we can provide with the following limitation:

|

Max. outer circle diameter: 152 m |

|

|

|

Max. outer circle diameter: 152 mm |

|

|

Max. tube material length: 6500 mm |

|

|

Max. finished part length: 3000 mm |

|

|

Mild steel: 8 mm |

|

|

Stainless steel: 4 mm |

|

|

Aluminum: 3 mm |

CNC Tube laser cutting eliminates all traditional marking out, sawing, drilling, deburring and shaping operations carried out with conventional tube processing. Traditional fixed costs of punches, clamps, tools and jigs are also eliminated.