- Precise: Laser cutting has higher cut precise than plasma cutting. - Speed: Plasma cutting cuts as much as five times faster than laser cutting. - Cutting material thickness: plasma cutting cuts mild steel till 75mm thick plate, w...

Share

- Precise: Laser cutting has higher cut precise than plasma cutting.

- Speed: Plasma cutting cuts as much as five times faster than laser cutting.

- Cutting material thickness: plasma cutting cuts mild steel till 75mm thick plate, which 6 times of the laser cutting that we can provide. The plasma cutting is a good cutting method for mild steel of low-to-medium thickness.

- Cost: Plasma cutting is more economical than laser cutting.

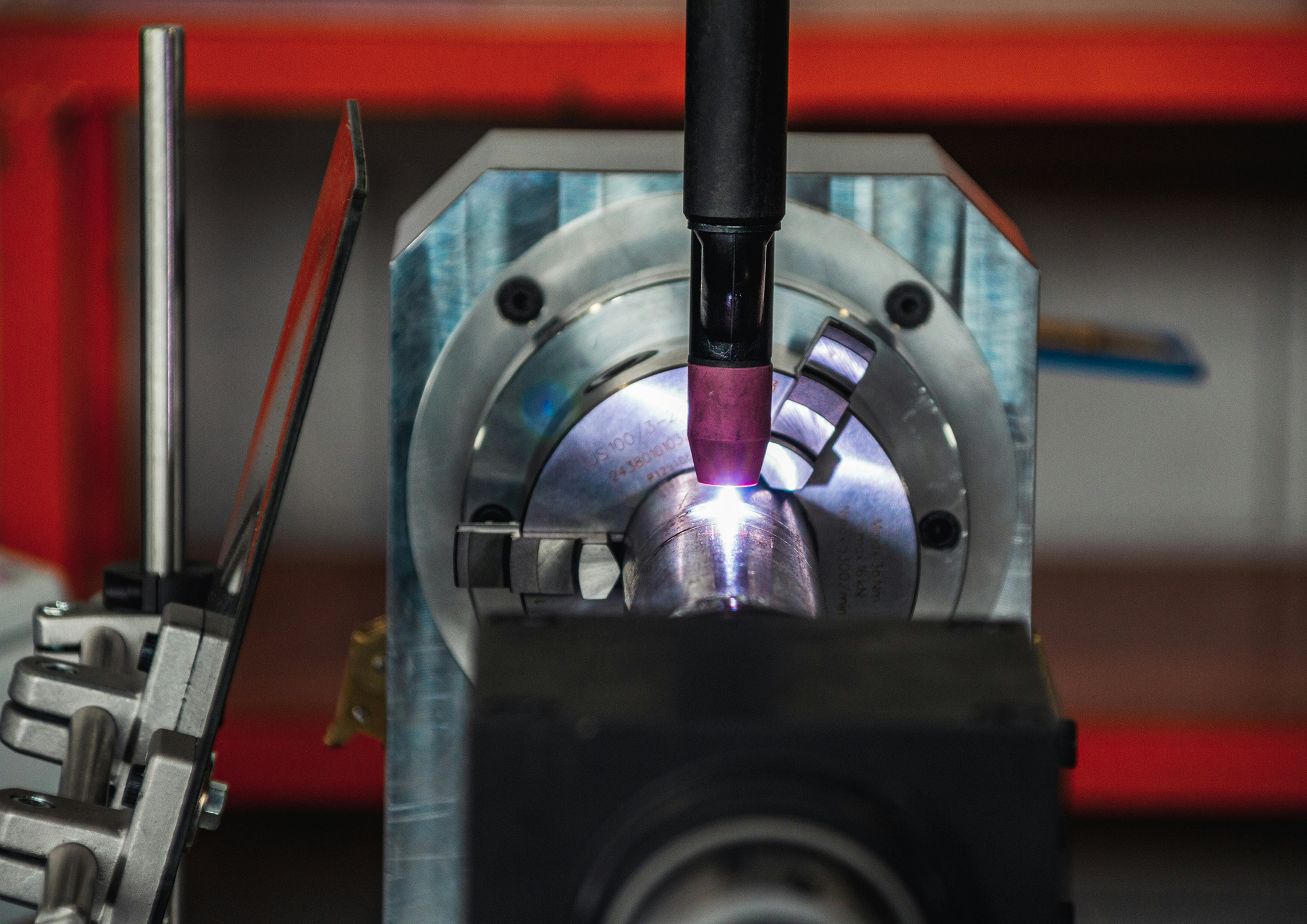

At Atlas Metal, plasma cutting is frequently used to perform bevel cuts for weld preparation. To weld the thicker component parts the thicker plate are required to be beveled edges to facilitate a weld joint with the correct amount of weld penetration. For the bevel it is not complex geometry with critical tolerance requirement, plasma cutting is good option thanks its high speed and low cost cutting.